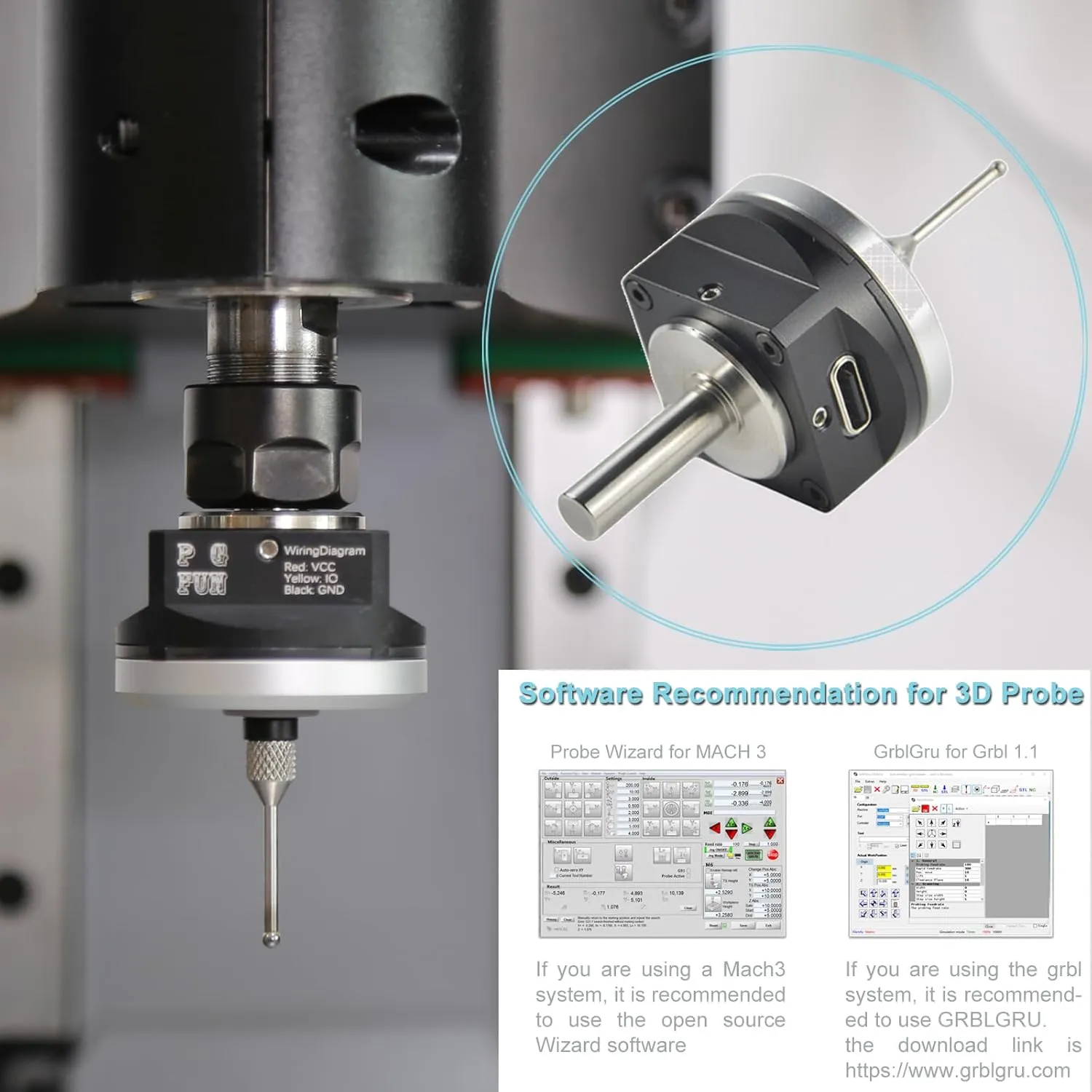

- This 3-coordinate XYZ axis CNC probe is designed for wide DIY CNC applications, like fast zero-point acquisitions, surface flatness acquisition, measuring workpiece geometries such as edges, holes, grooves, studs, angles and corners, workpiece scanning & digitizing. ( Tips: It's developed for DIY applications, not recommended for industrial use.)

- Main Specs: power: DC5-24V, NPN-NO wiring ( High-level IO signal output when powered and turns to Low-level signal output when Triggered), repeatability accuracy: 0.01 mm/ 0.0004 in, feed rate: 50-200 mm/min, over travel protection distance: XY- ±4mm/0.16 in, Z- 2mm/ 0.08in, XY axis trigger force: 0.5-0.82N, Z axis trigger force: 1.6 N. (Note: if working with a tool setter to test the height of the probe, please ensure the sensitivity of the tool setter is better/ trigger force less than 1.6 N.)

- Application: theoretically it can work with GRBL, MACH3, Mach4, Dynamotion, LiNUXCNC, UCCNC, Centroid CNC or any other CNC control software with a probing routine and a breakout board that will accept 3-port probe input (contact your software, and controller manufacturer or lookup forums for probe wiring and connections).

- Upgraded Digitizing CNC Touch Probe: the probe uses high-quality electronics for true high measurement precision and high repeatability, the fine frosted black oxidized aluminum alloy with a flat surface anti-roll/non-round shaped design, which makes it look great and protects the touch probe well from dropping. Besides, this tool can be modified to a tool setter by a tool setter base and flat tip.

- Package Includes: 3D touch probe x 1, cable x 2 m/ 6.5ft, allen wrench x 1, tungsten steel ball tip x 1, wire connector kit x 1 (to solve the lack of control board wiring ports and extend the wire ).